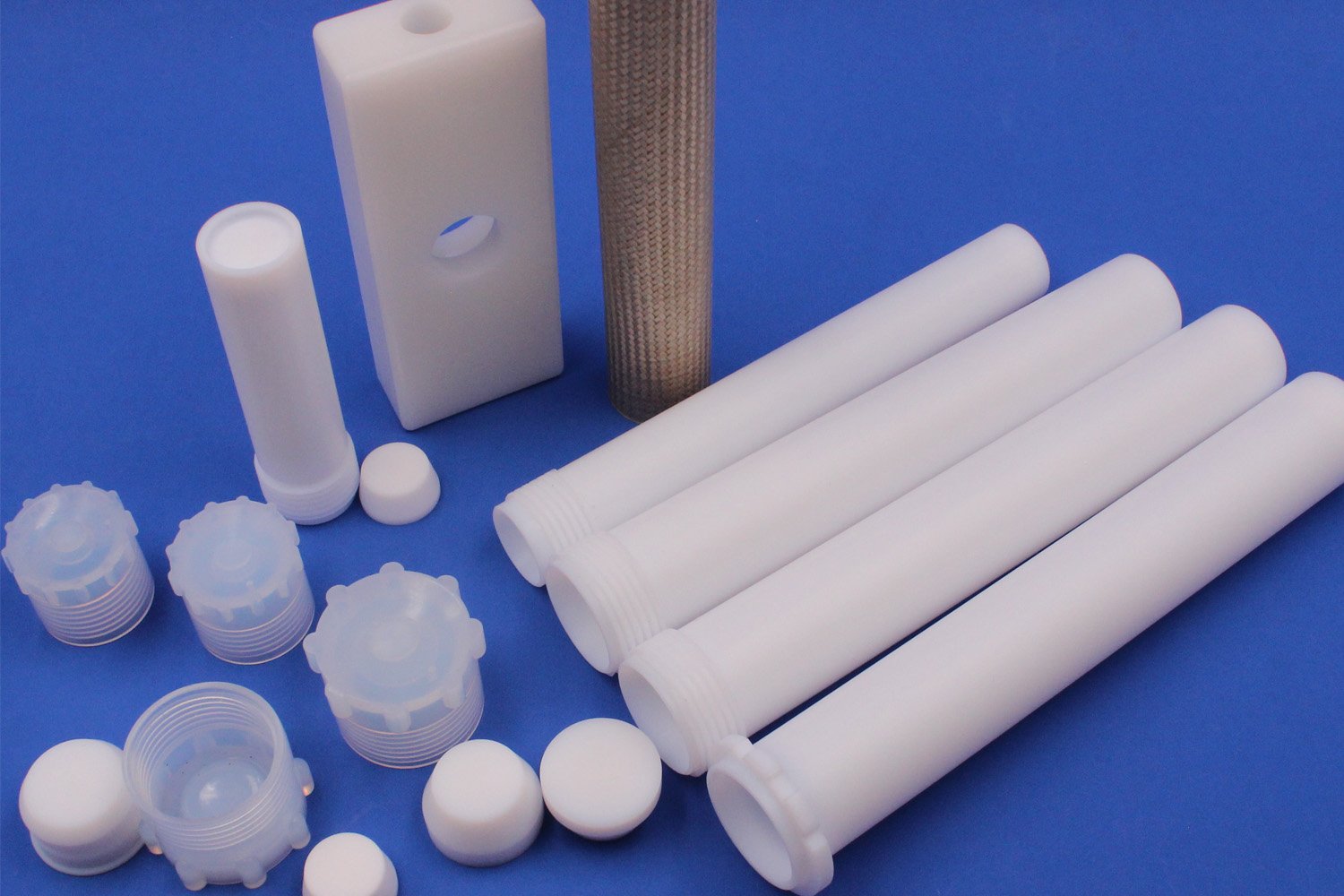

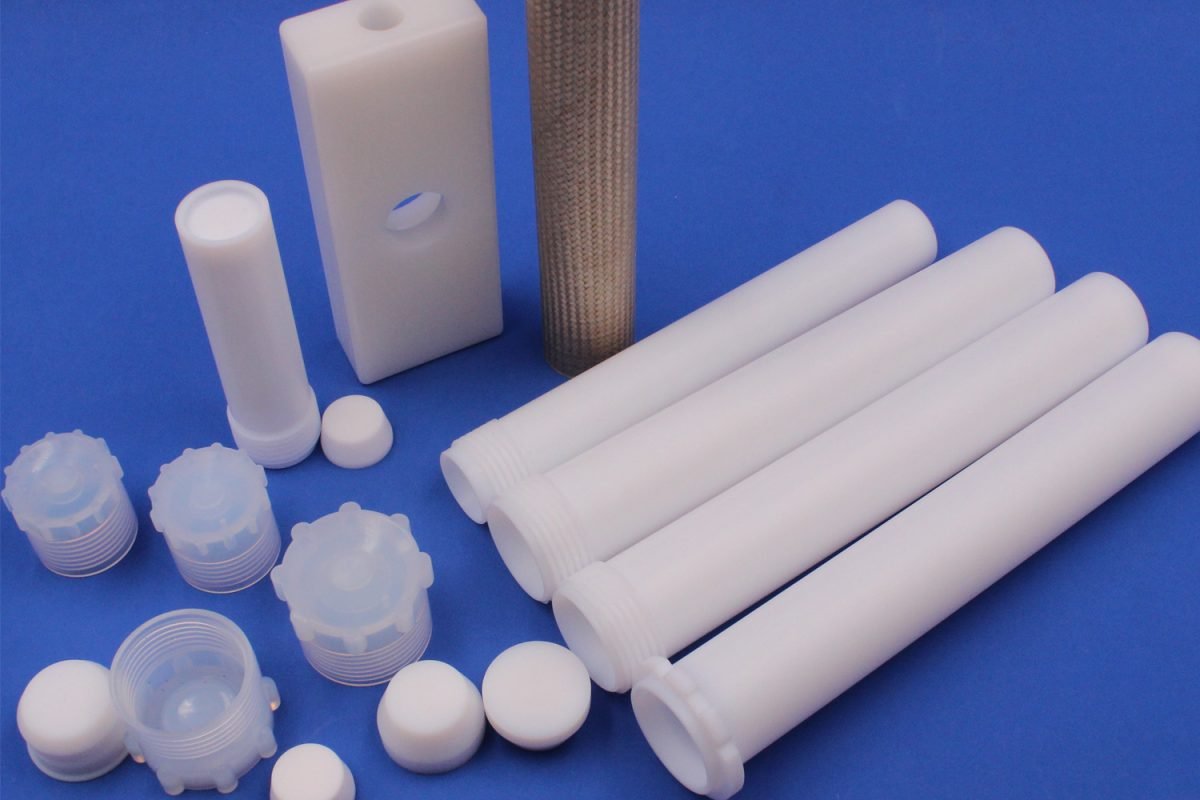

PTFE – Gaskets, Packing Rings, Thread Seal Tape, Bearings,Slide Rails,Piston Rings,Sliders,high frequency communication equipment components, printed circuit board (PCB), cable insulation layer, PTFE microporous membrane, air filtration membrane, Non stick pan coating, baking mold, labware and lab components(PTFE beaker, crucible, flask, vials).

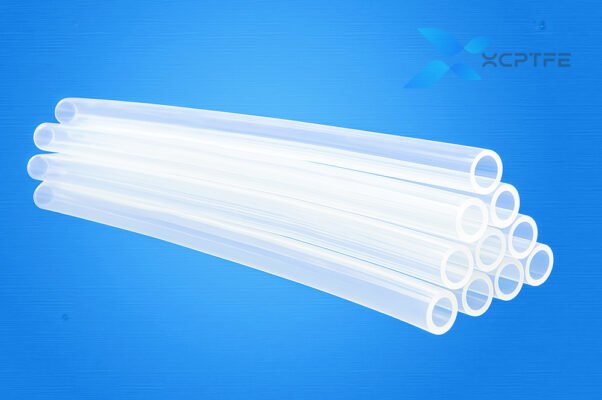

PFA – high purity chemical conveying pipe, heat exchange coil, insulating sleeve, beakers, flasks, volumetric flasks, pipette tips, valves, pump bodies, fittings, wafer carriers, lining and components of equipment, high insulation film, anti stick lining and gasket, special wire and cable insulation layer.

FEP – high purity chemical conveying pipe/tubing, insulation sleeve and sheath, coaxial cable insulation layer, high-temperature wire, thermocouple extension wire, agricultural greenhouse covering film, solar panel front film, high frequency circuit substrate, beakers, measuring cylinders, reagent bottles, three-way valves, connectors, heat sealing machine gripper, baking mold, industrial roller,

ETFE – air-filled cushions, tensile structures, special cable sheath(Jacket), insulation layer of data cable, lining for chemical equipment, sample vials and containers, components of pumps and valves, agricultural greenhouse covering film, solar panel front film.