Understanding FEP: A High-Performance Fluoropolymer

FEP (Fluorinated Ethylene Propylene), also known as FEP resin or F46, is a versatile and high-performance fluoropolymer. It is a copolymer of tetrafluoroethylene (TFE) and hexafluoropropylene (HFP). Its primary advantage is that it combines the exceptional properties of PTFE (Teflon®) with the melt-processability of a true thermoplastic, making it easier to fabricate into various forms.

Key Properties and Advantages

FEP is valued for its unique set of characteristics:

-

Excellent Chemical Resistance: It is highly inert and resistant to nearly all chemicals, similar to PTFE, making it ideal for corrosive environments.

-

Superb Electrical Insulation: FEP possesses a stable, low dielectric constant (around 2.1) and a very high volume resistivity over a wide range of frequencies and temperatures.

-

Broad Service Temperature Range: It performs reliably in temperatures from -200°C to +200°C.

-

Outstanding Non-Stick & Low Friction: It features excellent release properties and a low coefficient of friction.

-

High Transparency & Low Refractive Index: FEP films are highly transparent, with the lowest refractive index of any plastic.

-

Non-Flammability: It is inherently flame-retardant, meeting stringent safety standards.

Processing Methods

Unlike PTFE, FEP can be processed using standard thermoplastic techniques, which greatly expands its application potential. Key methods include:

-

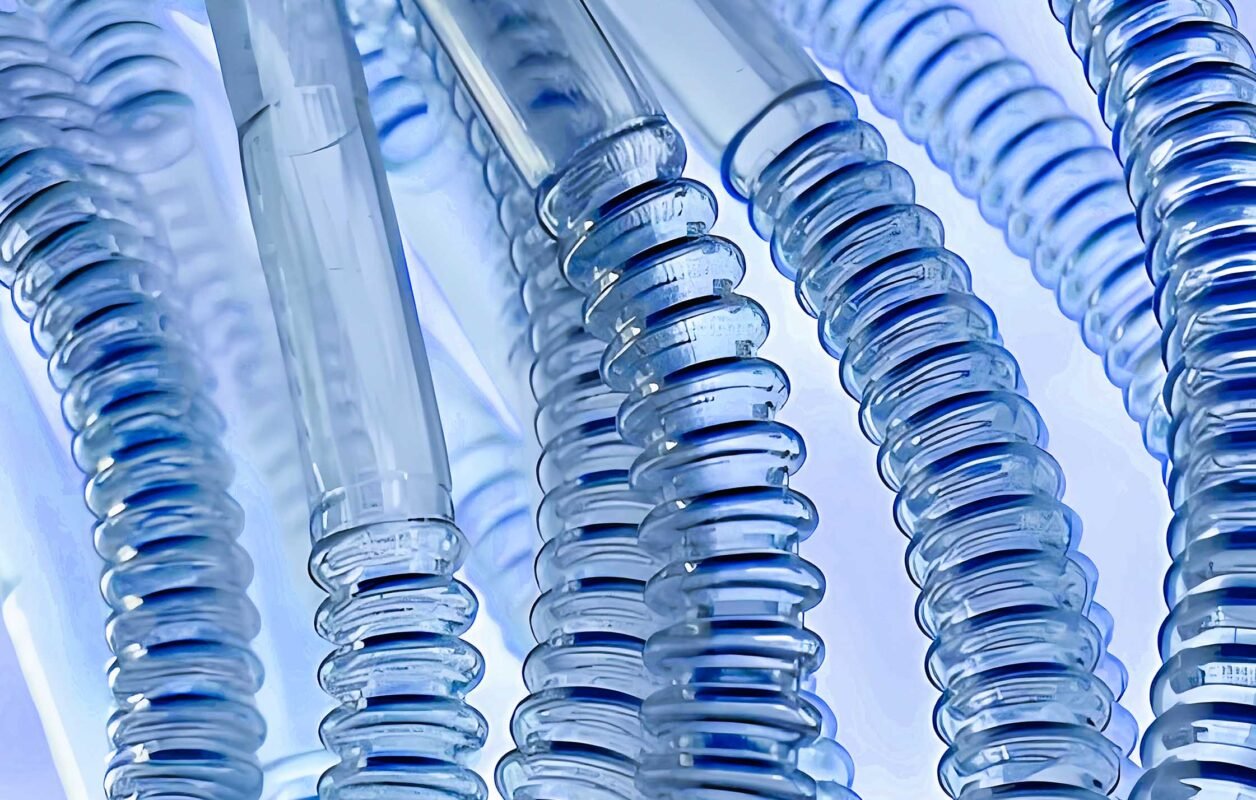

Extrusion: For producing wire insulation, tubes, and sheets.

-

Injection Molding: To create complex-shaped components.

-

Blow Molding: Primarily used for manufacturing high-clarity FEP films.

Typical Applications

Thanks to this property profile, FEP is critical in many advanced industries:

-

Wire & Cable: Used as insulation for high-temperature, high-frequency wires in 5G communications, aerospace, and computing.

-

Chemical Processing: Lining for pipes, valves, and tanks handling aggressive chemicals.

-

Electronics: As a dielectric layer for printed circuit boards.

-

Medical & Semiconductor: For high-purity fluid transfer tubing in medical devices and LCD manufacturing, where purity and stability are paramount.

Summary

FEP is an indispensable material in demanding sectors like electronics, chemical processing, and healthcare. Its unique blend of durability, stability, and processability ensures it remains a material of choice for cutting-edge applications.