Performance Comparison and Application Selection of PTFE / FEP / PFA

Choosing Between PTFE, FEP, and PFA: A Quick Guide

In the world of high-performance plastics, PTFE, FEP, and PFA are superstar fluoropolymers renowned for exceptional chemical resistance, non-stick properties, and ability to handle high temperatures. But knowing which one to choose is key to a successful design.

The Core Differences

While similar, their unique properties dictate their best uses.

-

PTFE (Polytetrafluoroethylene): The classic “Teflon.” It boasts the highest continuous operating temperature (260°C) and best dielectric properties. Its main drawback is that it cannot be melt-processed; it must be compressed and sintered, limiting part geometry. It’s also prone to creep.

-

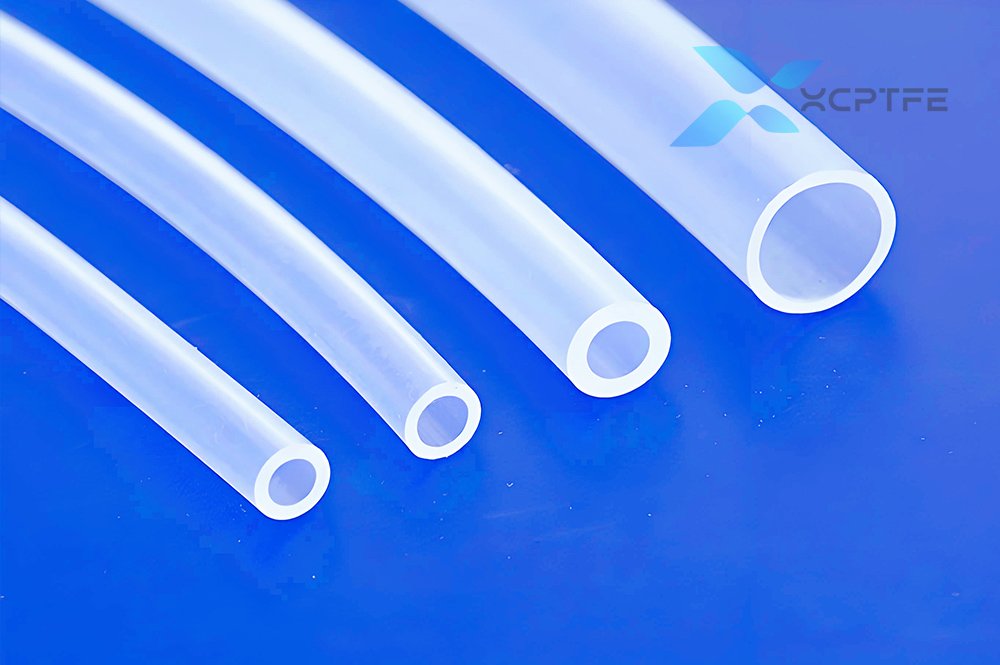

FEP (Fluorinated Ethylene Propylene): Often called “melt-processable PTFE.” Its biggest advantage is transparency and the ability to be used in injection molding and extrusion. However, it sacrifices some performance, with a lower maximum service temperature (205°C) and lower mechanical strength than PTFE or PFA.

-

PFA (Perfluoroalkoxy Alkane): The premium performer. It matches PTFE’s high-temperature resistance (260°C) and adds superior chemical resistance and mechanical properties, including excellent resistance to creep. Like FEP, it is transparent and melt-processable, allowing for the fabrication of complex, high-purity components. This comes at a higher cost.

Application Selection Guide

-

Choose PTFE for: High-temp seals, bearings, electrical insulators, and non-stick coatings for cookware. It’s the cost-effective choice for simple shapes where very high heat is needed.

-

Choose FEP for: Chemically resistant transparent sight glasses, light coverings, and lower-temperature wire insulation. It’s ideal when clarity and melt-processing are required for complex shapes under 205°C.

-

Choose PFA for: The most demanding jobs. It’s the standard for high-purity fluid handling in semiconductor and pharmaceutical industries, critical chemical process parts, and any application requiring the best combination of melt-processability, extreme temperature, and chemical resistance.

In short: For the best heat and price, pick PTFE. For clarity and processability under 205°C, pick FEP. For the ultimate performance in harsh or ultra-pure environments, invest in PFA.