CUSTOM PRODUCT CASE

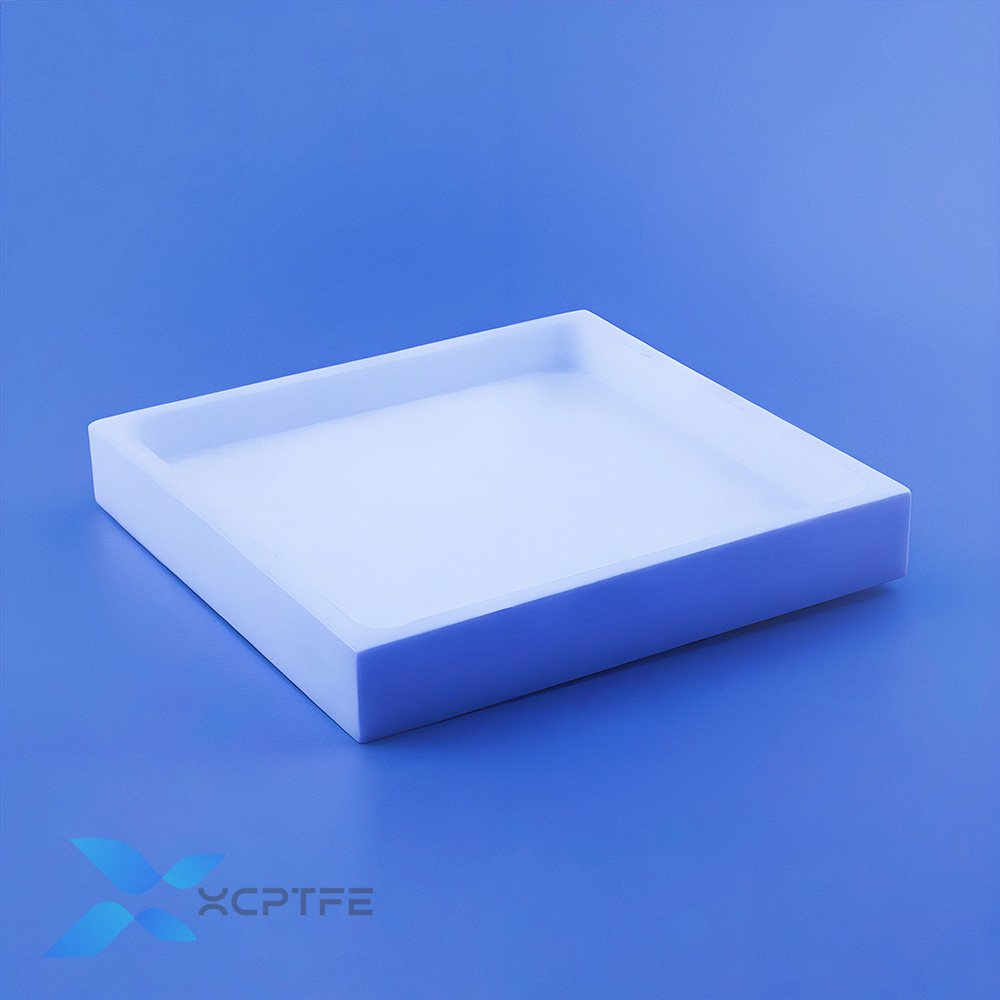

- Requires the highest temperature and widest chemical resistance, and a simple shape → Choose PTFE (by molding or turning)

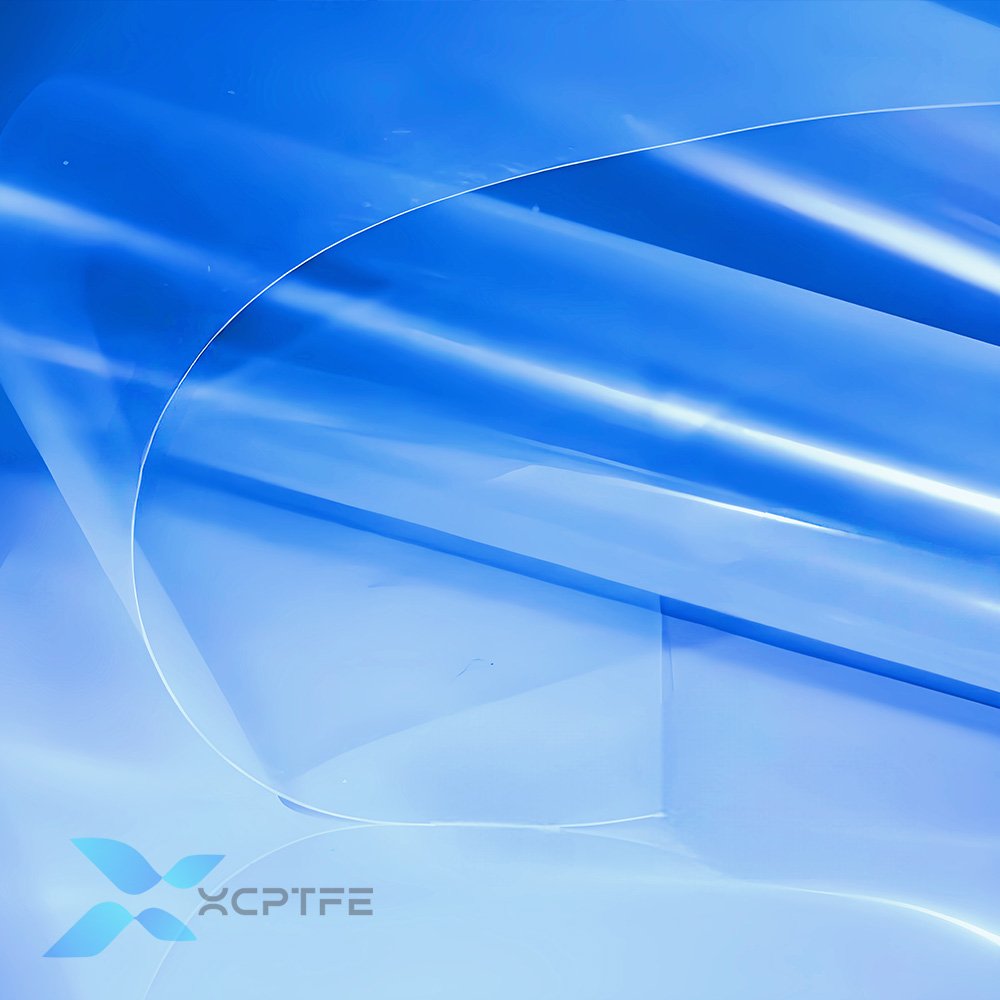

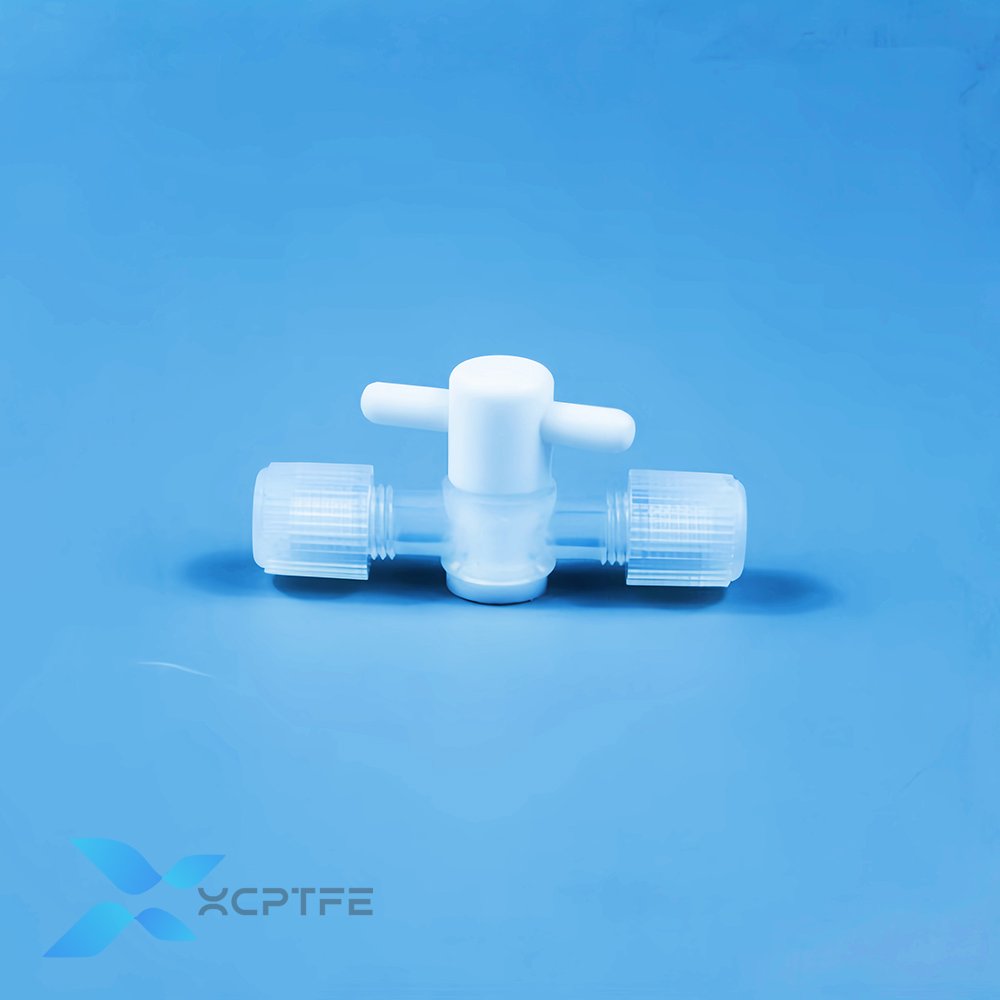

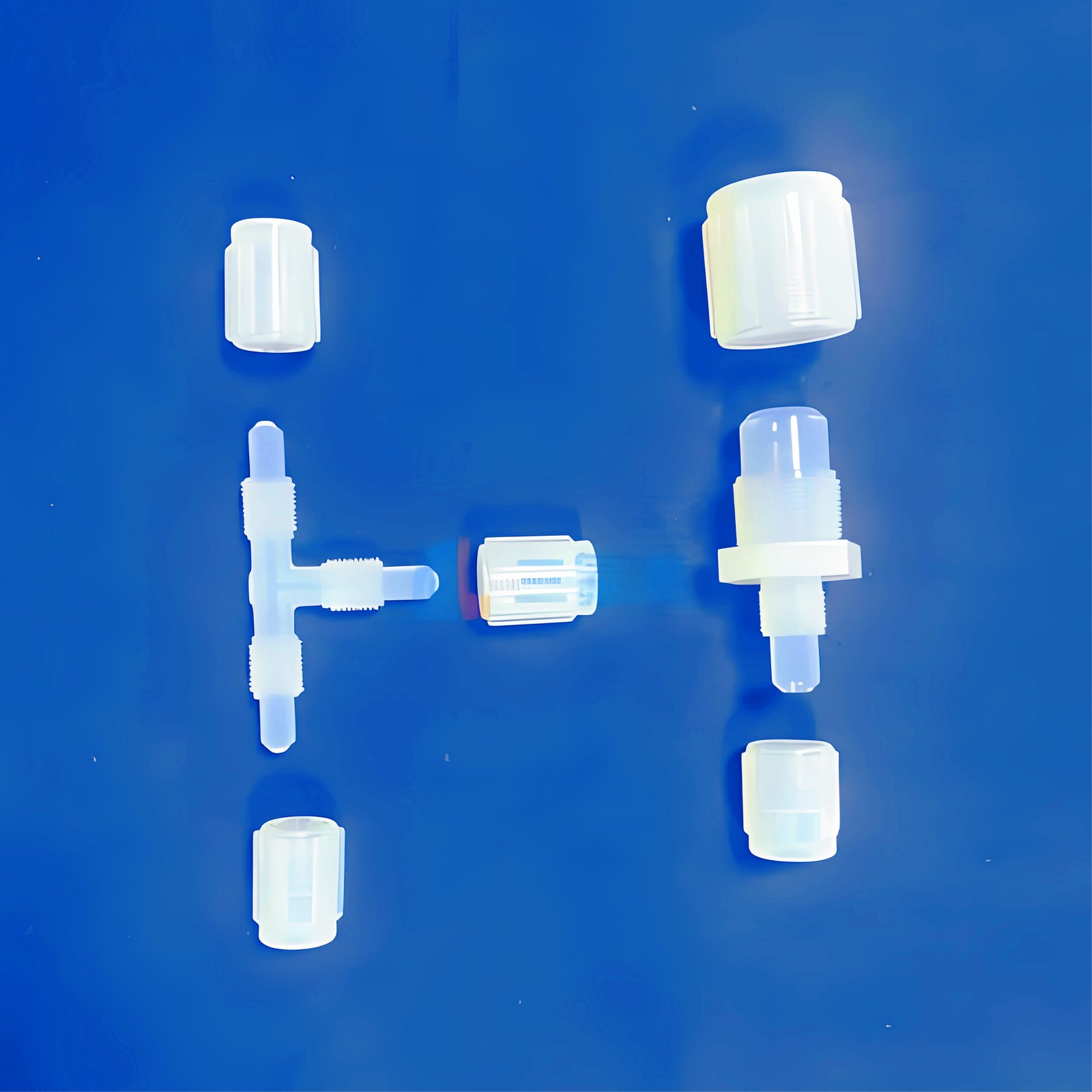

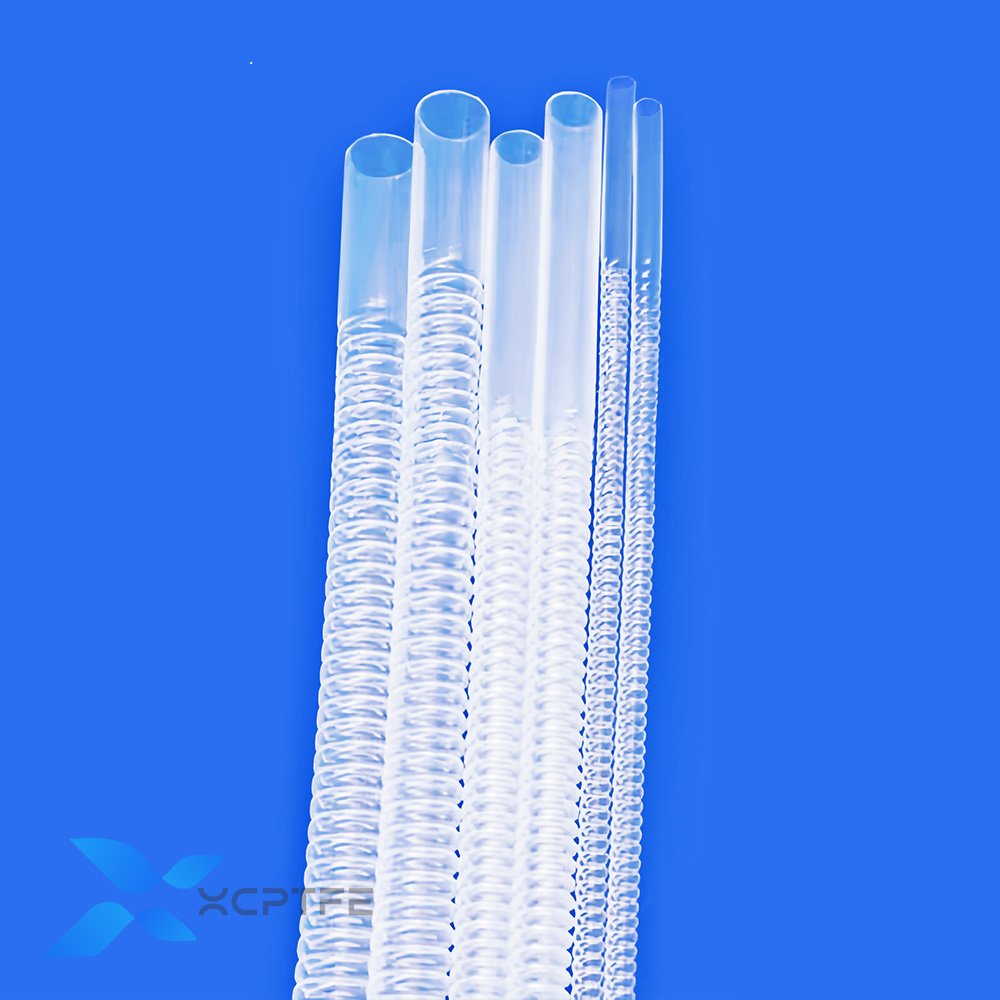

- Requires PTFE performance, but requires complex shape, injectability and high purity/transparency → Choose PFA

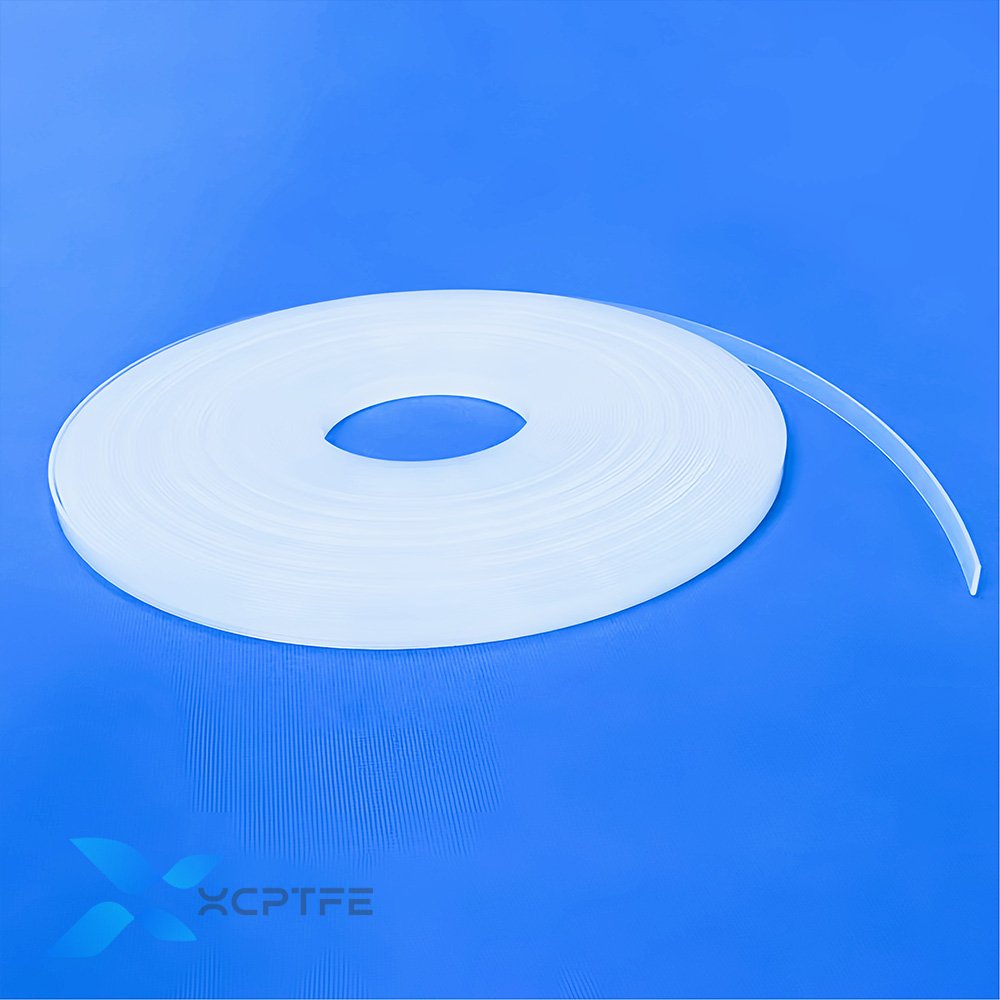

- Requires excellent transparency and melt processability, mainly used in films or pipes, cost sensitive → Choose FEP

- Requires extremely high mechanical strength, impact resistance, wear resistance, and weather resistance → Choose ETFE

You can choose the most suitable material based on specific application requirements such as temperature, pressure, chemical environment, mechanical load, transparency, regulatory requirements, etc. We support customizing fluoroplastic components that precisely meet the requirements.