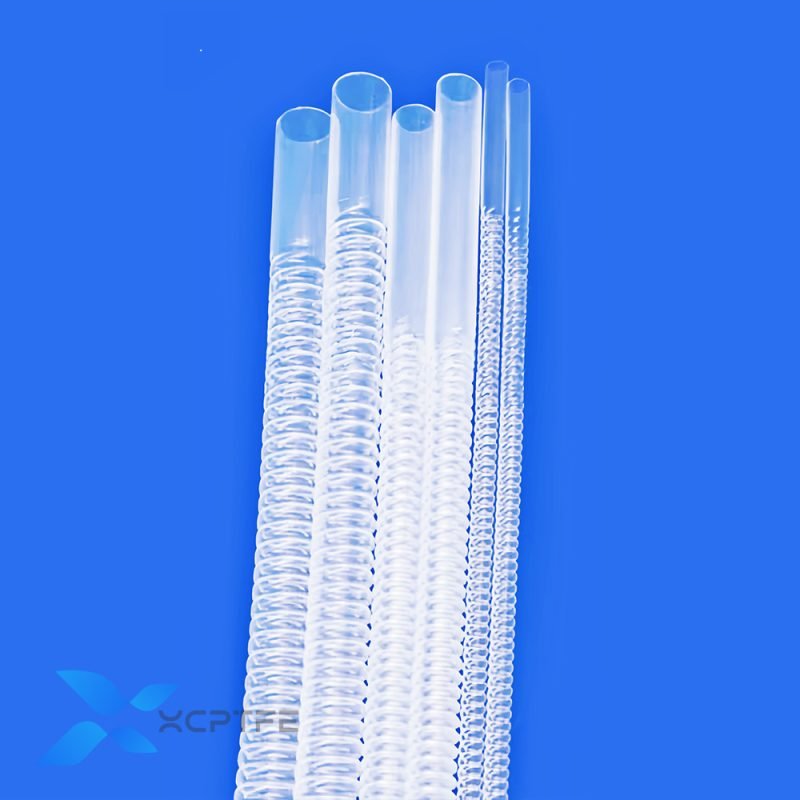

Custom FEP Corrugated Pipes/Tubes/Hose

- Resistant to all strong acids, alkalis, oxidants and organic solvents including aqua regia.

- Extremely low surface energy (non viscous), extremely low friction coefficient, excellent hydrophobicity and oleophobicity.

- Long time working temperature between -200°C and +200°C.

- Extremely high purity, odorless and non-toxic (at normal processing temperatures), excellent weather resistance (without aging).

- Highly transparent (transparent to UV band), with a light transmittance of>95% and extremely low haze.

- Excellent insulator.

Description

FEP corrugated pipe is a flexible pipe component made of FEP (fluorinated ethylene propylene copolymer) material with wavy folds. It is a key component in high-purity, highly corrosive fluid transportation systems.

1、 FEP material endows corrugated pipes with irreplaceable characteristics:

Ultra high chemical inertness: resistant to almost all strong acids, bases, oxidants, and organic solvents, such as aqua regia, hydrofluoric acid, nitric acid, etc.

Ultimate purity: It is inherently clean, with extremely low precipitation, and will not contaminate ultra pure chemicals or specialty gases.

Excellent Transparency: It has the highest transparency among fluoroplastics, making it easy to visually observe the fluid state, bubbles, and particulate matter inside the tube.

Excellent flexibility: The corrugated tube structure can be stretched, compressed, and bent, absorbing vibration and compensating for pipeline displacement.

Wide temperature resistance: Continuous use temperature range of about -200 ° C to+200 ° C.

2、 Main functions and functions

Flexible connection: compensates for alignment errors and connects two device interfaces that may have slight misalignment.

Vibration absorption: Installed near vibration sources such as pumps and compressors to reduce pulse and vibration transmission and protect sensitive equipment.

Compensation displacement: Absorbs changes in pipeline length caused by thermal expansion and contraction to prevent stress in the system.

Easy to install and maintain: Its flexibility makes installation in complex spaces easier, and also facilitates equipment replacement and maintenance.

3、 Typical application industries

Semiconductor manufacturing industry: transporting ultra pure chemicals and corrosive gases in equipment such as wafer etching and cleaning.

Photovoltaic industry: During the production of polycrystalline silicon and silicon wafers, corrosive slurries are transported.

Biopharmaceuticals: In aseptic production processes, flexible connections that require sterility and online sterilization (SIP) are used for bioreactors, filtration systems, and other applications.

Chemical analysis and laboratory: used for connecting analytical instruments and experimental devices for easy observation and replacement.

4、 Important precautions

Pressure resistance: Its pressure resistance is usually lower than that of hard pipes of the same specification. When selecting, it is necessary to confirm that the working pressure is within a safe range.

Installation method: When bending, do not exceed its minimum bending radius to avoid excessive stretching or compression to prevent damage.

Joint form: PFA flanges or standard threaded joints (such as VCR) are usually used at both ends ®), To ensure the sealing and no contamination at the metal interface.

Heat sealing: It is the most common processing method for FEP films. Accurate control of temperature, pressure, and time is necessary. Insufficient temperature can lead to insufficient sealing strength; Excessive temperature or pressure can cause thinning, perforation, or decomposition of the film.

Welding (hot air welding, hot plate welding): Accurate temperature control is also required. The outlet temperature of the welding gun needs to be calibrated with a thermocouple to avoid local overheating caused by direct blowing.

Demoulding properties: FEP is an excellent demoulding material due to its extremely low surface energy. But this also means that printing and gluing on its surface are extremely difficult and must be processed.

Mechanical protection: FEP film is relatively soft and easily scratched. During the process of unwinding and using, it is necessary to ensure that the guide rollers are smooth and free of burrs, and it is best to wear gloves during operation.

2. In the extrusion of pipes and cables

Extruder cleaning: Before stopping the machine, the barrel must be thoroughly cleaned with general-purpose plastics such as polyethylene (PE) or polypropylene (PP). Heat sensitive materials such as ABS and POM should never be used to clean the machine to prevent residue from carbonizing and decomposing at high temperatures during the next start-up, which could contaminate FEP products.

Screw design: Low shear screws are usually used to avoid excessive shear heat causing local overheating and decomposition of the material.

Mold design: The flow channel should be highly smooth to avoid dead corners and prevent material retention and decomposition.

3. In 3D printing (as a consumable tube)

Bowden Tube: FEP tube is commonly used as a consumable tube for 3D printers due to its low friction coefficient and temperature resistance.

Length: It should not be too long to reduce pushing resistance.

Inner diameter matching: The inner diameter needs to be closely matched with the diameter of the consumables (usually 1.75mm). If the gap is too large, it will cause inaccurate control, and if it is too small, it will increase resistance.

Regular inspection: After prolonged use, the interior may be worn or accumulate debris, requiring regular inspection and replacement to prevent printing quality issues.

4. Safety and Health (Most Important!)

Processing ventilation: Any high-temperature processing operation must be carried out under a good fume hood or strong exhaust system to eliminate any trace harmful gases that may be generated.

Personal protection: Operators should wear gas masks (organic vapor filter boxes), goggles, and chemical resistant gloves.

Leakage treatment: In case of overheating and smoking, immediately cut off the power supply, evacuate personnel quickly to upwind areas, and have professional personnel wear self-contained breathing apparatus (SCBA) for treatment. Do not inhale smoke through your mouth.

Fire hazard: FEP itself is not flammable, but once burned, it will produce highly toxic and corrosive smoke. Carbon dioxide or dry powder fire extinguishers are required.