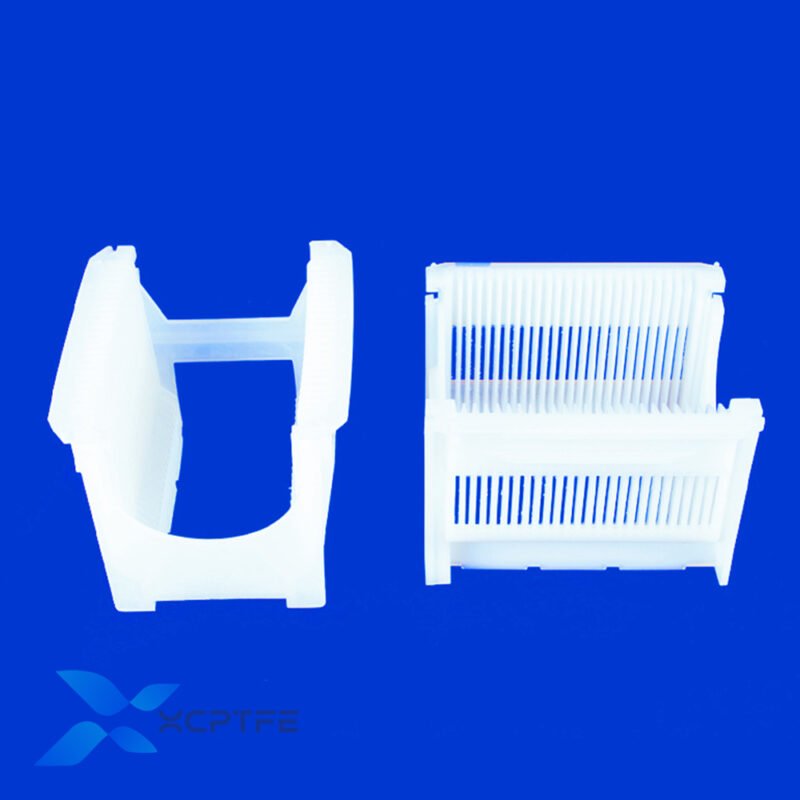

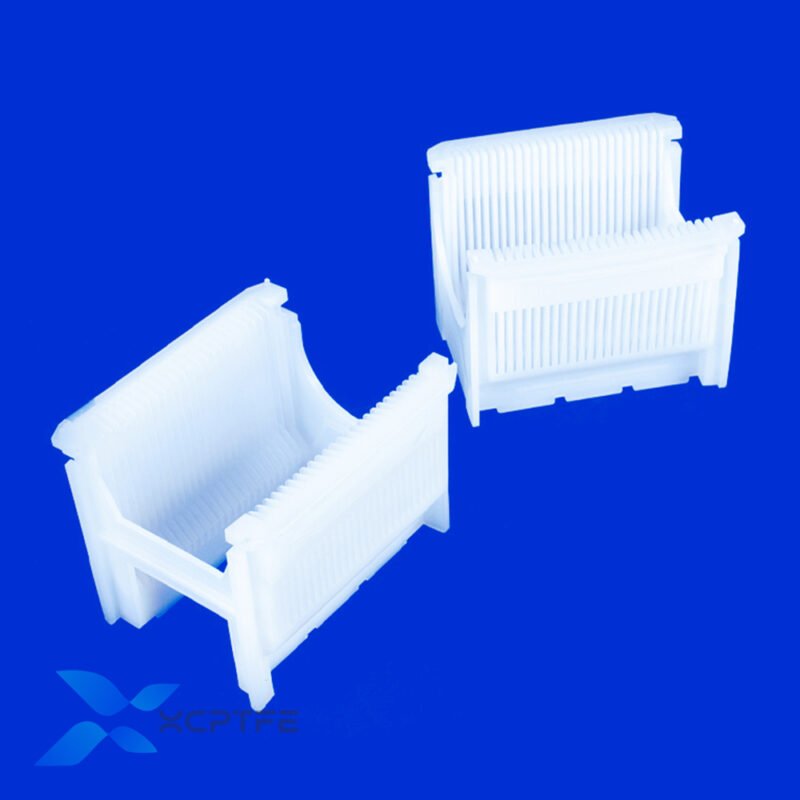

Custom PFA Wafer Carrier / Cassette / Basket

- Resistant to all strong acids, alkalis, oxidants and organic solvents including hydrofluoric acid.

- Smooth surface, extremely low friction coefficient, not adhere to any substances, easy to clean.

- Long time working temperature between -200°C and +260°C. Short working time at 300°C

- High purity & not contaminate experimental samples.

- Good transparency facilitates observation needs in experiments.

Description

The PFA wafer carrier is a critical component in the semiconductor manufacturing process, designed for the safe handling and transportation of silicon wafers. Also commonly referred to as a PFA wafer cassette or PFA wafer basket, this essential tool is constructed from high-purity PFA (Perfluoroalkoxy) material. This polymer is selected for its exceptional chemical resistance and mechanical stability, ensuring zero contamination in ultra-clean production environments.

Its primary function is to hold wafers securely during various wet process stages, including etching, cleaning, and rinsing with aggressive chemicals like acids and solvents. The inherent properties of PFA make this PFA boat ideal for withstanding high temperature processes, often exceeding 200°C, without degrading or leaching impurities. The high purity grade of the raw material is paramount to preventing the introduction of metallic ions or particles that could destroy the functionality of microchips.

Given the sensitive nature of its application, many manufacturers offer custom solutions. A reliable supplier can provide PFA wafer carriers tailored to specific requirements, such as unique wafer sizes, slot counts, or handle configurations. This customization ensures perfect compatibility with existing automated handling equipment and process tools. Therefore, selecting a high-quality PFA wafer basketfrom a trusted supplier is a vital step in maintaining high yield and product reliability in semiconductor fabrication.