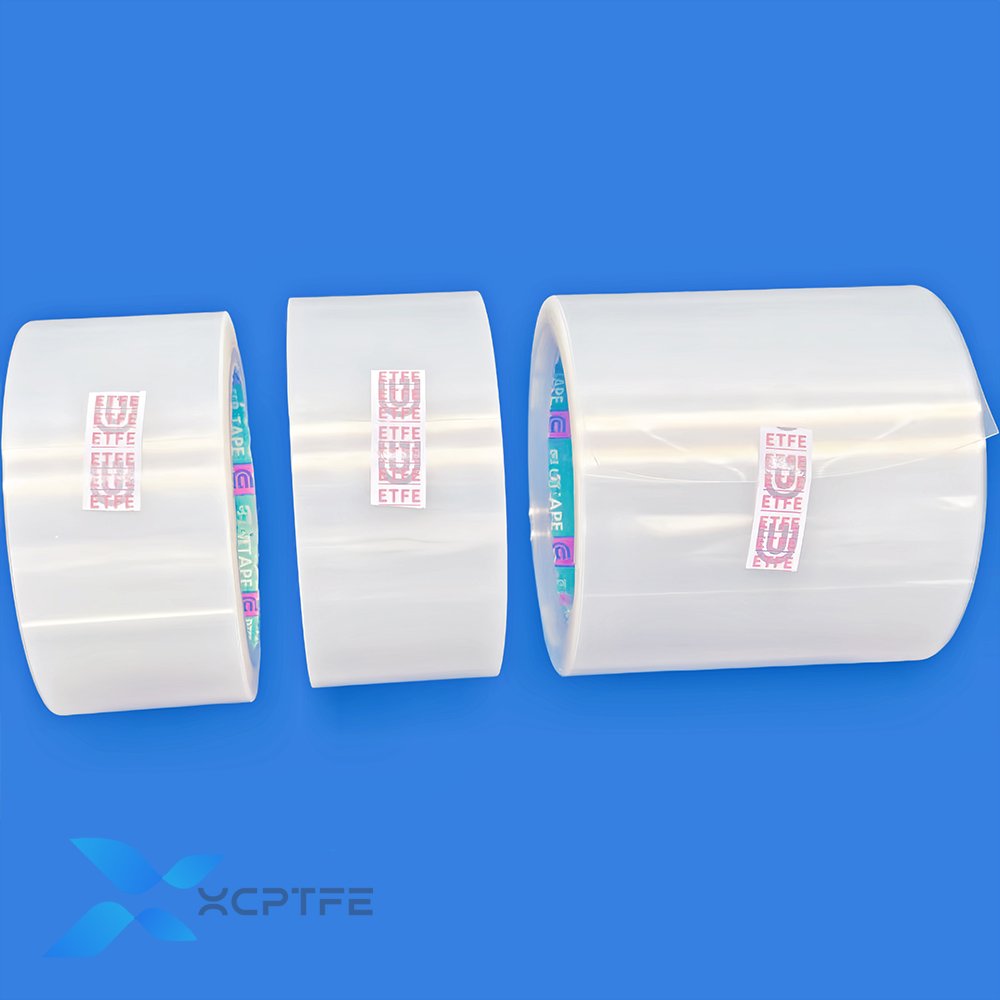

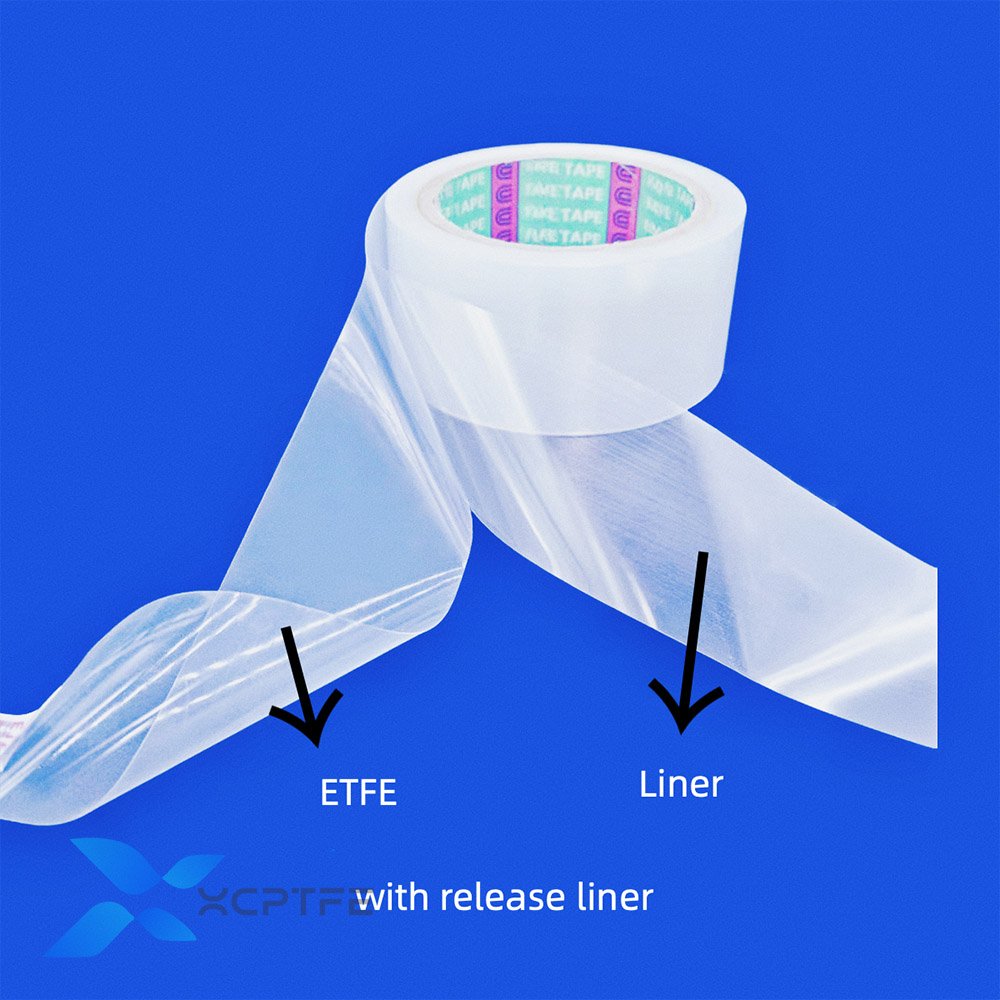

ETFE Film Adhesive Tape with/without Liner

Price range: $15.00 through $310.00

Type: ETFE Film Adhesive Tape with/without Liner

Material: 100% ETFE

Feature: High tensile strength, wear-resistant, scratch resistant, corrosion-resistant, non sticky, strong flexibility,highly transparent, flame retardant, weatherability.

Customization:available

Item NO.: S259302

Reviews

There are no reviews yet.